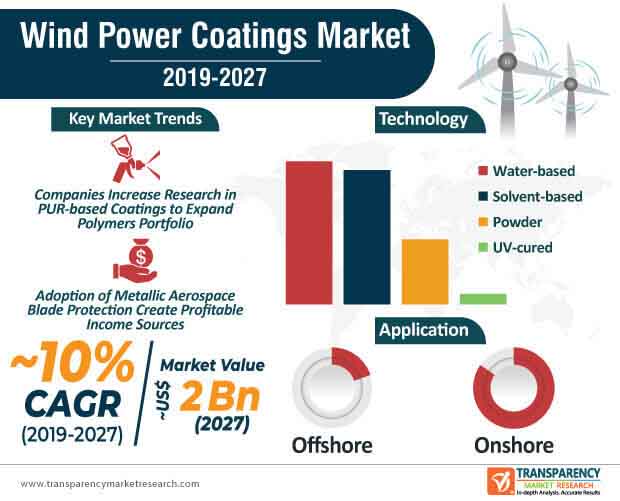

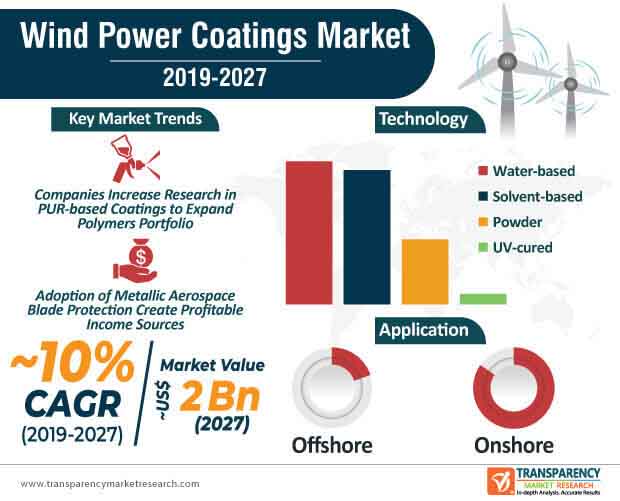

Wind Power Coatings Market to surpass US$ 2 Bn by 2027

Published by TMR Research Insights

Posted on August 6, 2021

18 min readLast updated: January 21, 2026

Published by TMR Research Insights

Posted on August 6, 2021

18 min readLast updated: January 21, 2026

Growing atrocities of unpredictable weather conditions have triggered the demand for efficacious wind power coatings. Manufacturing companies are aiming to expand their product portfolio of polymer coatings for wind towers and blades that are witnessing an increase in demand. As such, the polymer coatings type segment dominates the wind power coatings market, in terms of value and volume, and is estimated to reach a volume of ~178,200 kilo liters by the end of 2022. Hence, manufacturers are innovating in new polymer coatings. For instance, German supplier of high-tech polymer materials Convestro, has gained expertise in PUR (Polyurethanes)-based topcoats that offer lasting corrosion protection for wind towers.

Companies in the market for wind power coatings are increasing their research activities to develop high-performance wind energy coatings. They are adding value to polymer coatings by offering exceptional gloss and color retention attributes in coatings. Furthermore, companies in the wind power coatings market are increasing production capacities to manufacture PUR-based coatings to provide lasting mechanical performance and protection from abrasion for smooth functionality of turbine blades. Companies are helping stakeholders in onshore and offshore segments to achieve high productivity by increasing the availability of low-VOC content coatings.

Strong expertise with attention to detail makes our market research reports stand apart. Download PDF Brochure –

Rise in Use of Graphene Additives to Manufacture Eco-friendly Coatings

Companies in the wind power coatings market are boosting their credibility credentials by developing greener corrosion protection coatings. Apart from gaining stability in polymer-based coatings, manufacturers are increasing efforts to gain trust and reliability in the global market landscape by developing eco-friendly coatings. This goal is being achieved with the help of graphene additives.

Exceptional mechanical strength and thermal conductive properties of graphene are gaining increased popularity in the market for wind power coatings. Hence, manufacturers are combining the properties of graphene with solvent- and water-based coatings to develop eco-friendly coatings. As such, the water-based technology segment accounts for the highest revenue in the wind power coatings market. This segment is expected to reach a value of ~US$ 800 Mn by 2027.

Moreover, manufacturers are increasing production capabilities to develop water-based coatings to address the growing concerns of corrosion in onshore and offshore applications. Companies are experimenting by combining graphene with other corrosion-protection pigments to offer anti-corrosion function in coatings.

Request for Covid-19 Impact Analysis on Wind Power Coatings Market :

High Industry Standards Lead to Innovations

High industry standards in the European wind power coatings market are giving rise to efficient coating systems. There is a growing demand for advanced coatings that improve operational life of wind turbines. Hence, manufacturers in the wind power coatings market are increasing the availability of protective coatings and gel coatings for blades of wind power plants. As such, the onshore blade application segment of the wind power coatings market is estimated to reach an output of ~66,000 kilo liters by 2027. Hence, manufacturers are increasing efforts to meet productivity and long-lasting performance without the need for maintenance requirements of end users.

Companies in the wind power coatings market are gaining efficacy in waterborne topcoats that provide low solvent emissions. They are tapping into opportunities in coatings for rotor blades to offer leading-edge protection.

Buy our Premium Research Report on Wind Power Coatings Market @

Innovations in offshore application are contributing to the exponential growth of the market, even though onshore application dominates the wind power coatings market in terms of volume and value. Companies are adopting new approaches such as using the aerospace technology to develop leading-edge protection systems. These novel coatings are being increasingly used for offshore wind turbines. Continuous product developments in the wind power coatings market are helping stakeholders in the offshore segment to achieve cost-efficiency. Cost-efficiency is being achieved through advanced coating systems that eliminate the need for intervention due to rain erosion. Thus, improved coatings are paving the way for lighter wind turbine blades.

On the other hand, new product offerings for onshore applications are helping manufacturers in the wind power coatings market to accomplish business stability. As such, the onshore application segment accounts for ~97% of the wind power coatings market share. However, there is a need for better products to address erosion due to rain. Hence, companies in the wind power coatings market are adopting the aerospace technology to enhance the blades operational life.

Analysts’ Viewpoint

The wind power coatings market is largely consolidated with three major players accounting to ~75% of the market share. Companies are focusing on niche requirements for fewer coats and faster curing in painting operations. They are increasing awareness about the inspection technology to improve the operational life of wind turbine blades in onshore and offshore applications.

However, conventional coating methods, such as using zinc powder lead to growing concerns about the degradation of the environment. Hence, manufacturers are developing coatings with graphene additives to help develop greener coatings. Companies should invest in powder and water-based coatings, since they are projected for exponential growth.

Wind Power Coatings Market: Overview

Wind Power Coatings Market: Key Growth Drivers

Wind Power Coatings Market: Major Challenges

Wind Power Coatings Market: Opportunities

Asia Pacific Dominates Wind Power Coatings Market

Extensive Usage of Wind Power Coatings in Onshore Application

Key Developments in Wind Power Coatings Market

Chemicals & Materials Industry battles Tangible Impact of Economic and Cultural changes, Stay Updated on the Latest Trends in Chemicals & Materials Market @ https://www.transparencymarketresearch.com/chemical-market-reports-2.html

About Us

Transparency Market Research is a global market intelligence company, providing global business information reports and services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insight for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants, use proprietary data sources and various tools and techniques to gather, and analyze information.

Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports.

Contact

Transparency Market Research

State Tower,

90 State Street,

Suite 700,

Albany NY – 12207

United States

USA – Canada Toll Free: 866-552-3453

Email: sales@transparencymarketresearch.com

Follow Us: Twitter | LinkedIn

Blog: https://tmrblog.com

Growing atrocities of unpredictable weather conditions have triggered the demand for efficacious wind power coatings. Manufacturing companies are aiming to expand their product portfolio of polymer coatings for wind towers and blades that are witnessing an increase in demand. As such, the polymer coatings type segment dominates the wind power coatings market, in terms of value and volume, and is estimated to reach a volume of ~178,200 kilo liters by the end of 2022. Hence, manufacturers are innovating in new polymer coatings. For instance, German supplier of high-tech polymer materials Convestro, has gained expertise in PUR (Polyurethanes)-based topcoats that offer lasting corrosion protection for wind towers.

Companies in the market for wind power coatings are increasing their research activities to develop high-performance wind energy coatings. They are adding value to polymer coatings by offering exceptional gloss and color retention attributes in coatings. Furthermore, companies in the wind power coatings market are increasing production capacities to manufacture PUR-based coatings to provide lasting mechanical performance and protection from abrasion for smooth functionality of turbine blades. Companies are helping stakeholders in onshore and offshore segments to achieve high productivity by increasing the availability of low-VOC content coatings.

Strong expertise with attention to detail makes our market research reports stand apart. Download PDF Brochure –

Rise in Use of Graphene Additives to Manufacture Eco-friendly Coatings

Companies in the wind power coatings market are boosting their credibility credentials by developing greener corrosion protection coatings. Apart from gaining stability in polymer-based coatings, manufacturers are increasing efforts to gain trust and reliability in the global market landscape by developing eco-friendly coatings. This goal is being achieved with the help of graphene additives.

Exceptional mechanical strength and thermal conductive properties of graphene are gaining increased popularity in the market for wind power coatings. Hence, manufacturers are combining the properties of graphene with solvent- and water-based coatings to develop eco-friendly coatings. As such, the water-based technology segment accounts for the highest revenue in the wind power coatings market. This segment is expected to reach a value of ~US$ 800 Mn by 2027.

Moreover, manufacturers are increasing production capabilities to develop water-based coatings to address the growing concerns of corrosion in onshore and offshore applications. Companies are experimenting by combining graphene with other corrosion-protection pigments to offer anti-corrosion function in coatings.

Request for Covid-19 Impact Analysis on Wind Power Coatings Market :

High Industry Standards Lead to Innovations

High industry standards in the European wind power coatings market are giving rise to efficient coating systems. There is a growing demand for advanced coatings that improve operational life of wind turbines. Hence, manufacturers in the wind power coatings market are increasing the availability of protective coatings and gel coatings for blades of wind power plants. As such, the onshore blade application segment of the wind power coatings market is estimated to reach an output of ~66,000 kilo liters by 2027. Hence, manufacturers are increasing efforts to meet productivity and long-lasting performance without the need for maintenance requirements of end users.

Companies in the wind power coatings market are gaining efficacy in waterborne topcoats that provide low solvent emissions. They are tapping into opportunities in coatings for rotor blades to offer leading-edge protection.

Buy our Premium Research Report on Wind Power Coatings Market @

Innovations in offshore application are contributing to the exponential growth of the market, even though onshore application dominates the wind power coatings market in terms of volume and value. Companies are adopting new approaches such as using the aerospace technology to develop leading-edge protection systems. These novel coatings are being increasingly used for offshore wind turbines. Continuous product developments in the wind power coatings market are helping stakeholders in the offshore segment to achieve cost-efficiency. Cost-efficiency is being achieved through advanced coating systems that eliminate the need for intervention due to rain erosion. Thus, improved coatings are paving the way for lighter wind turbine blades.

On the other hand, new product offerings for onshore applications are helping manufacturers in the wind power coatings market to accomplish business stability. As such, the onshore application segment accounts for ~97% of the wind power coatings market share. However, there is a need for better products to address erosion due to rain. Hence, companies in the wind power coatings market are adopting the aerospace technology to enhance the blades operational life.

Analysts’ Viewpoint

The wind power coatings market is largely consolidated with three major players accounting to ~75% of the market share. Companies are focusing on niche requirements for fewer coats and faster curing in painting operations. They are increasing awareness about the inspection technology to improve the operational life of wind turbine blades in onshore and offshore applications.

However, conventional coating methods, such as using zinc powder lead to growing concerns about the degradation of the environment. Hence, manufacturers are developing coatings with graphene additives to help develop greener coatings. Companies should invest in powder and water-based coatings, since they are projected for exponential growth.

Wind Power Coatings Market: Overview

Wind Power Coatings Market: Key Growth Drivers

Wind Power Coatings Market: Major Challenges

Wind Power Coatings Market: Opportunities

Asia Pacific Dominates Wind Power Coatings Market

Extensive Usage of Wind Power Coatings in Onshore Application

Key Developments in Wind Power Coatings Market

Chemicals & Materials Industry battles Tangible Impact of Economic and Cultural changes, Stay Updated on the Latest Trends in Chemicals & Materials Market @ https://www.transparencymarketresearch.com/chemical-market-reports-2.html

About Us

Transparency Market Research is a global market intelligence company, providing global business information reports and services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insight for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants, use proprietary data sources and various tools and techniques to gather, and analyze information.

Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports.

Contact

Transparency Market Research

State Tower,

90 State Street,

Suite 700,

Albany NY – 12207

United States

USA – Canada Toll Free: 866-552-3453

Email: sales@transparencymarketresearch.com

Follow Us: Twitter | LinkedIn

Blog: https://tmrblog.com

Explore more articles in the Research Reports category